Common Materials Make Supercapacitor

Common Materials Make Supercapacitor

Researchers combine cement, carbon black, and water to create a durable electricity storage system.

Electricity storage is more important than ever. Energy used to be locked up in fuels—piles of coal or tanks of gasoline—that could stay in place until needed. The move to electrification both in production of renewable energy and the conversion from conventional cars to EVs means electricity needs to be stored in bulk and over spans of hours or days.

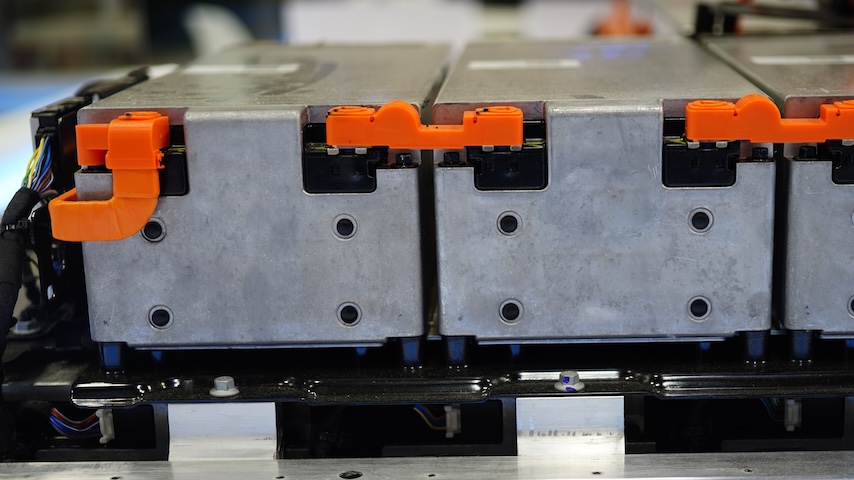

While the lithium-ion battery has proven to be a powerhouse for the electrified economy, its internal chemistry is dependent on somewhat uncommon materials. In addition to lithium, cobalt, manganese, and nickel are needed for advanced batteries.

In July 2023, however, researchers at the Massachusetts Institute of Technology unveiled an electricity storage system based on an exceedingly common material: cement.

“Cement is, after water, the most consumed material on Earth,” said Franz-Josef Ulm, faculty director of the Concrete Sustainability Hub and a professor of civil and environmental engineering at MIT. His team created a cement-based supercapacitor capable of storing enough electricity to power a house all day long.

As Ulm explained, the production of cement results in carbon emissions, and the scale of the industry—cement is a major component in the manufacture of concrete—is so great that cement accounts for roughly 8 percent of worldwide carbon dioxide emissions. “One motivation of this work was to curb the environmental impact of cement and concrete by adding a second function to the material in addition to strength: Energy storage.”

Cement and concrete have been used for thermal energy storage due to their ability to retain heat. But electricity is trickier since cement is an insulator. But Ulm and his colleagues realized that at the microscopic scale, cement is very porous, giving it a very large internal surface area. That surface area can be used to store electrons as long as it is covered with a conductive material and an electrolyte for connecting potentially unconnected portions of the conductor.

Ulm and his colleagues realized that carbon black, essentially a finely ground charcoal, was used in electricity storage devices called supercapacitors and was readily obtainable. The microscopic structure of the carbon black also provides a large surface area for electrons.

The recipe was simple, Ulm said. “We prepared a dry mix of cement and carbon black, then mixed in water and superplasticizer (a synthetic polymer used for making high-strength concrete) to obtain a slurry,” he said. The team let the material harden in plastic tubes for four weeks, cut the cylinders into disks, and soaked these cement electrodes in a potassium chloride electrolyte.

Two of these charcoal-colored electrodes, separated by a membrane, form a supercapacitor: Electrons from one electrode are pulled into the other, charging the system and storing electricity for use.

The team worked to discover the right mix of cement, carbon, and water, plus the electrode thickness that allows for the greatest electricity storage density per volume.

More for You: Using Concrete to Carry a Charge

“We found that up to 10 percent carbon black by volume provides both sufficient strength and enough energy storage capacity,” Ulm said.

“This material allows us to store between 20 to 220 Wh per cubic meter,” he said.

In the research reported in the paper, “Carbon-cement supercapacitors as a scalable bulk energy storage solution,” published in the Proceedings of the National Academy of Sciences, the team linked three dime-size cylinders to provide enough electricity to power a 3 V light-emitting diode. The goal is to develop a block the size of a 12 V car battery, Ulm continued, which could then be stacked into walls or foundations that could serve both structural as well as energy storage functions.

The team estimates that a 45-cubic-meter system (about the size of a small backyard swimming pool) would store enough electricity to power a typical house for a day.

“In parallel, we are looking into the possibility of using the energy storage capacity for on-road charging EVs by electromagnetic induction,” Ulm said.

To be sure, there’s little chance that future EVs will run off cement supercapacitors. The energy density of lithium-ion batteries is orders of magnitude greater than what the MIT system can hold. But the combination of structural performance and low cost could enable the supercapacitor to have dual roles in largescale infrastructure projects. For instance, one potential application would be in the foundation of onshore wind turbines, providing both physical stability and energy storage.

“Cement is available everywhere, as is carbon black, in contrast to lithium,” Ulm said. “Hence, the cost should be much lower than lithium-ion batteries. In addition, carbon black can be obtained from a large variety of processes. My favorite one is the separation of methane into hydrogen and carbon to obtain hydrogen as an energy source. In return, the carbon could be used for energy storage in our technology.”

Jeffrey Winters is editor in chief of Mechanical Engineering magazine.

While the lithium-ion battery has proven to be a powerhouse for the electrified economy, its internal chemistry is dependent on somewhat uncommon materials. In addition to lithium, cobalt, manganese, and nickel are needed for advanced batteries.

In July 2023, however, researchers at the Massachusetts Institute of Technology unveiled an electricity storage system based on an exceedingly common material: cement.

“Cement is, after water, the most consumed material on Earth,” said Franz-Josef Ulm, faculty director of the Concrete Sustainability Hub and a professor of civil and environmental engineering at MIT. His team created a cement-based supercapacitor capable of storing enough electricity to power a house all day long.

As Ulm explained, the production of cement results in carbon emissions, and the scale of the industry—cement is a major component in the manufacture of concrete—is so great that cement accounts for roughly 8 percent of worldwide carbon dioxide emissions. “One motivation of this work was to curb the environmental impact of cement and concrete by adding a second function to the material in addition to strength: Energy storage.”

Cement and concrete have been used for thermal energy storage due to their ability to retain heat. But electricity is trickier since cement is an insulator. But Ulm and his colleagues realized that at the microscopic scale, cement is very porous, giving it a very large internal surface area. That surface area can be used to store electrons as long as it is covered with a conductive material and an electrolyte for connecting potentially unconnected portions of the conductor.

Ulm and his colleagues realized that carbon black, essentially a finely ground charcoal, was used in electricity storage devices called supercapacitors and was readily obtainable. The microscopic structure of the carbon black also provides a large surface area for electrons.

The recipe was simple, Ulm said. “We prepared a dry mix of cement and carbon black, then mixed in water and superplasticizer (a synthetic polymer used for making high-strength concrete) to obtain a slurry,” he said. The team let the material harden in plastic tubes for four weeks, cut the cylinders into disks, and soaked these cement electrodes in a potassium chloride electrolyte.

Two of these charcoal-colored electrodes, separated by a membrane, form a supercapacitor: Electrons from one electrode are pulled into the other, charging the system and storing electricity for use.

The team worked to discover the right mix of cement, carbon, and water, plus the electrode thickness that allows for the greatest electricity storage density per volume.

More for You: Using Concrete to Carry a Charge

“We found that up to 10 percent carbon black by volume provides both sufficient strength and enough energy storage capacity,” Ulm said.

“This material allows us to store between 20 to 220 Wh per cubic meter,” he said.

In the research reported in the paper, “Carbon-cement supercapacitors as a scalable bulk energy storage solution,” published in the Proceedings of the National Academy of Sciences, the team linked three dime-size cylinders to provide enough electricity to power a 3 V light-emitting diode. The goal is to develop a block the size of a 12 V car battery, Ulm continued, which could then be stacked into walls or foundations that could serve both structural as well as energy storage functions.

The team estimates that a 45-cubic-meter system (about the size of a small backyard swimming pool) would store enough electricity to power a typical house for a day.

“In parallel, we are looking into the possibility of using the energy storage capacity for on-road charging EVs by electromagnetic induction,” Ulm said.

To be sure, there’s little chance that future EVs will run off cement supercapacitors. The energy density of lithium-ion batteries is orders of magnitude greater than what the MIT system can hold. But the combination of structural performance and low cost could enable the supercapacitor to have dual roles in largescale infrastructure projects. For instance, one potential application would be in the foundation of onshore wind turbines, providing both physical stability and energy storage.

“Cement is available everywhere, as is carbon black, in contrast to lithium,” Ulm said. “Hence, the cost should be much lower than lithium-ion batteries. In addition, carbon black can be obtained from a large variety of processes. My favorite one is the separation of methane into hydrogen and carbon to obtain hydrogen as an energy source. In return, the carbon could be used for energy storage in our technology.”

Jeffrey Winters is editor in chief of Mechanical Engineering magazine.

Leading Hard-to-Decarbonize Industries to Zero Emissions

Some processes inherently produce a lot of carbon emissions, but groups are working to wrestle them under control.