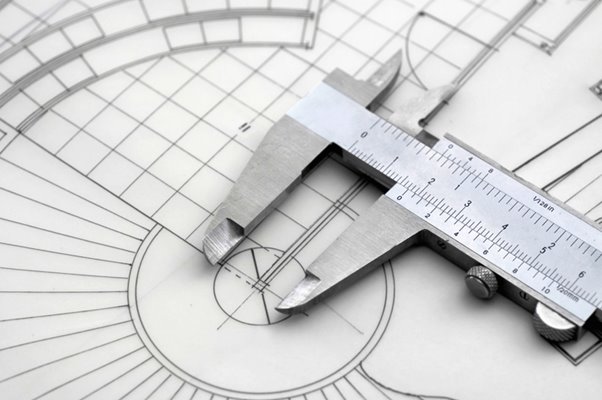

Modern GD&T (Geometric Dimensioning and Tolerancing) inspection practice in industry has moved away from simple pass/fail gaging, and increasingly uses measurement equipment that produces numerical results. It’s becoming more important for engineers and others to know how to define numerical values to measure and report at the inspection stage.

This includes hand tools such as height gages and dial indicators, as well as technology such as CMM's (Coordinate Measuring Machines), roundness testers, and 3D laser scanners. A major challenge in using these technologies for GD&T inspection has been a lack of standard definitions for measured values, which has led to significant inconsistencies in the measured values calculated by different systems. This course reviews the ASME Y14.45 definitions for measured values and how to calculate them, as well as providing industry best practices on the content of GD&T inspection reports.

By participating in this course, you will learn how to successfully:

- Examine a GD&T drawing and identify which numerical values would require verification on an inspection report according to ASME standards, and which would not

- Describe the actual value of a given geometric tolerance in terms of a zone, and recognize it on a depiction of an actual part feature

- Identify the correct adjustments available and calculate measured values for form, orientation, location, and runout tolerances from indicator measurement data

- Compare the options available when reporting actual values for multi-feature GD&T applications, such as Position tolerances on hole patterns

- Describe potential root causes for discrepancies in GD&T inspection results, relating to metrology software programming and calculation algorithms

- Complete a GD&T inspection report which includes Method A conformance, Method B measured values, and Method C supplemental data as per the ASME Y14.45-2021 Standard

Who should attend?

Quality Engineers, Design Engineers, Inspectors, Engineering Managers, Supplier Quality Engineers, CMM Programmers, Manufacturing Engineers - anyone who is involved in creating, reviewing, and interpreting GD&T inspection reports.

This course complements Geometric Dimensioning & Tolerancing Fundamentals and expects prerequisite knowledge of the fundamentals in the topic.

Course Materials (included in purchase of course)

- Digital course notes via ASME’s Learning Platform

- Exercise sheets

- Example drawings, measurement data examples and data reports

Supplemental Course Materials (not included with course, purchase separately)

- ASME Y14.5-2018 Standard

- ASME Y14.45-2021 Standard

- GeoTol Pro book or other GD&T textbooks and pocket guides based on ASME Y14.5 Standard are useful but not necessary

This ASME Virtual Classroom course is held live with an instructor on our online learning platform.

Certificate of completion will be issued to registrants who successfully attend and complete the course.